Axisymmetric rotor#

This notebook demonstrates the process of running a Workbench service on a local machine to solve both 2D general axisymmetric rotor and 3D rotor models using PyMechanical. It includes steps for uploading project files, executing scripts, downloading results, and displaying output images.

[1]:

import os

import pathlib

[2]:

from ansys.workbench.core import launch_workbench

from ansys.mechanical.core import connect_to_mechanical

Launch the Workbench service on the local machine using specific options. Define the working directory and subdirectories for assets, scripts, and geometry databases (agdb). The launch_workbench function starts a Workbench session with the specified directory.

[3]:

workdir = pathlib.Path("__file__").parent

[4]:

assets = workdir / "assets"

scripts = workdir / "scripts"

[5]:

wb = launch_workbench(client_workdir=str(workdir.absolute()))

Upload the project files to the server using the upload_file_from_example_repo method. The files uploaded are axisymmetric_model.agdb, rotor_3d_model.agdb.

[6]:

wb.upload_file_from_example_repo("axisymmetric-rotor/agdb/axisymmetric_model.agdb")

wb.upload_file_from_example_repo("axisymmetric-rotor/agdb/rotor_3d_model.agdb")

Uploading axisymmetric_model.agdb: 100%|██████████| 2.52M/2.52M [00:00<00:00, 70.3MB/s]

Uploading rotor_3d_model.agdb: 100%|██████████| 2.52M/2.52M [00:00<00:00, 84.6MB/s]

Execute a Workbench script (project.wbjn) to define the project and load the geometry. The log file is set to wb_log_file.log and the name of the system created is stored in sys_name and printed.

[7]:

export_path = 'wb_log_file.log'

wb.set_log_file(export_path)

sys_name = wb.run_script_file(str((assets / "project.wbjn").absolute()), log_level='info')

print(sys_name)

['SYS', 'SYS 4']

Start a PyMechanical server for the system and create a PyMechanical client session to solve the 2D general axisymmetric rotor model. The project directory is printed to verify the connection.

[8]:

server_port = wb.start_mechanical_server(system_name=sys_name[1])

[9]:

mechanical = connect_to_mechanical(ip='localhost', port=server_port)

[10]:

print(mechanical.project_directory)

C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\

Read and execute the script axisymmetric_rotor.py via the PyMechanical client to mesh and solve the 2D general axisymmetric rotor model. The output of the script is printed.

[11]:

with open(scripts / "axisymmetric_rotor.py") as sf:

mech_script = sf.read()

mech_output = mechanical.run_python_script(mech_script)

print(mech_output)

{"Total Deformation": "0.79262294403210676 [mm]", "Total Deformation 2": "0.93934788182426 [mm]"}

Specify the Mechanical directory for the Modal Campbell Analysis and fetch the working directory path. Download the solver output file (solve.out) from the server to the client’s current working directory and print its contents.

[12]:

mechanical.run_python_script(f"solve_dir=ExtAPI.DataModel.AnalysisList[2].WorkingDir")

result_solve_dir_server = mechanical.run_python_script(f"solve_dir")

print(f"All solver files are stored on the server at: {result_solve_dir_server}")

All solver files are stored on the server at: C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-6\MECH\

[13]:

solve_out_path = os.path.join(result_solve_dir_server, "solve.out")

[14]:

def write_file_contents_to_console(path):

"""Write file contents to console."""

with open(path, "rt") as file:

for line in file:

print(line, end="")

[15]:

current_working_directory = os.getcwd()

mechanical.download(solve_out_path, target_dir=current_working_directory)

solve_out_local_path = os.path.join(current_working_directory, "solve.out")

write_file_contents_to_console(solve_out_local_path)

os.remove(solve_out_local_path)

Downloading dns:///127.0.0.1:54649:C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-6\MECH\solve.out to C:\Users\ansys\actions-runner\_work\pyworkbench-examples\pyworkbench-examples\pyworkbench-examples\doc\source\examples\axisymmetric-rotor\solve.out: 100%|██████████| 80.0k/80.0k [00:00<?, ?B/s]

Ansys Mechanical Enterprise

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2024 R2 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2024 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2024 R2

Point Releases and Patches installed:

Ansys Service Pack 2024 R2.01

Ansys Service Pack 2024 R2.02

Ansys Service Pack 2024 R2.03

Ansys, Inc. License Manager 2024 R2

Ansys, Inc. License Manager 2024 R2.01

Ansys, Inc. License Manager 2024 R2.02

Ansys, Inc. License Manager 2024 R2.03

Discovery 2024 R2

Discovery 2024 R2.01

Discovery 2024 R2.02

Discovery 2024 R2.03

Core WB Files 2024 R2

Core WB Files 2024 R2.01

Core WB Files 2024 R2.02

Core WB Files 2024 R2.03

SpaceClaim 2024 R2

SpaceClaim 2024 R2.01

SpaceClaim 2024 R2.02

SpaceClaim 2024 R2.03

Icepak (includes CFD-Post) 2024 R2

Icepak (includes CFD-Post) 2024 R2.01

Icepak (includes CFD-Post) 2024 R2.02

Icepak (includes CFD-Post) 2024 R2.03

CFD-Post only 2024 R2

CFD-Post only 2024 R2.01

CFD-Post only 2024 R2.02

CFD-Post only 2024 R2.03

CFX (includes CFD-Post) 2024 R2

CFX (includes CFD-Post) 2024 R2.01

CFX (includes CFD-Post) 2024 R2.02

CFX (includes CFD-Post) 2024 R2.03

Chemkin 2024 R2

Chemkin 2024 R2.01

Chemkin 2024 R2.02

Chemkin 2024 R2.03

EnSight 2024 R2

EnSight 2024 R2.01

EnSight 2024 R2.02

EnSight 2024 R2.03

FENSAP-ICE 2024 R2

FENSAP-ICE 2024 R2.01

FENSAP-ICE 2024 R2.02

FENSAP-ICE 2024 R2.03

Fluent (includes CFD-Post) 2024 R2

Fluent (includes CFD-Post) 2024 R2.01

Fluent (includes CFD-Post) 2024 R2.02

Fluent (includes CFD-Post) 2024 R2.03

Polyflow (includes CFD-Post) 2024 R2

Polyflow (includes CFD-Post) 2024 R2.01

Polyflow (includes CFD-Post) 2024 R2.02

Polyflow (includes CFD-Post) 2024 R2.03

Forte (includes EnSight) 2024 R2

Forte (includes EnSight) 2024 R2.01

Forte (includes EnSight) 2024 R2.02

Forte (includes EnSight) 2024 R2.03

ICEM CFD 2024 R2

ICEM CFD 2024 R2.01

ICEM CFD 2024 R2.02

ICEM CFD 2024 R2.03

TurboGrid 2024 R2

TurboGrid 2024 R2.01

TurboGrid 2024 R2.02

TurboGrid 2024 R2.03

Speos 2024 R2

Speos 2024 R2.01

Speos 2024 R2.02

Speos 2024 R2.03

Speos HPC 2024 R2

Speos HPC 2024 R2.01

Speos HPC 2024 R2.02

Speos HPC 2024 R2.03

optiSLang 2024 R2

optiSLang 2024 R2.01

optiSLang 2024 R2.02

optiSLang 2024 R2.03

Remote Solve Manager Standalone Services 2024 R2

Remote Solve Manager Standalone Services 2024 R2.01

Remote Solve Manager Standalone Services 2024 R2.02

Remote Solve Manager Standalone Services 2024 R2.03

Additive 2024 R2

Additive 2024 R2.01

Additive 2024 R2.02

Additive 2024 R2.03

Aqwa 2024 R2

Aqwa 2024 R2.01

Aqwa 2024 R2.02

Aqwa 2024 R2.03

Autodyn 2024 R2

Autodyn 2024 R2.01

Autodyn 2024 R2.02

Autodyn 2024 R2.03

Customization Files for User Programmable Features 2024 R2

Customization Files for User Programmable Features 2024 R2.01

Customization Files for User Programmable Features 2024 R2.02

Customization Files for User Programmable Features 2024 R2.03

LS-DYNA 2024 R2

LS-DYNA 2024 R2.01

LS-DYNA 2024 R2.02

LS-DYNA 2024 R2.03

Mechanical Products 2024 R2

Mechanical Products 2024 R2.01

Mechanical Products 2024 R2.02

Mechanical Products 2024 R2.03

Motion 2024 R2

Motion 2024 R2.01

Motion 2024 R2.02

Motion 2024 R2.03

Sherlock 2024 R2

Sherlock 2024 R2.01

Sherlock 2024 R2.02

Sherlock 2024 R2.03

Sound - SAS 2024 R2

Sound - SAS 2024 R2.01

Sound - SAS 2024 R2.02

Sound - SAS 2024 R2.03

ACIS Geometry Interface 2024 R2

ACIS Geometry Interface 2024 R2.01

ACIS Geometry Interface 2024 R2.02

ACIS Geometry Interface 2024 R2.03

AutoCAD Geometry Interface 2024 R2

AutoCAD Geometry Interface 2024 R2.01

AutoCAD Geometry Interface 2024 R2.02

AutoCAD Geometry Interface 2024 R2.03

Catia, Version 4 Geometry Interface 2024 R2

Catia, Version 4 Geometry Interface 2024 R2.01

Catia, Version 4 Geometry Interface 2024 R2.02

Catia, Version 4 Geometry Interface 2024 R2.03

Catia, Version 5 Geometry Interface 2024 R2

Catia, Version 5 Geometry Interface 2024 R2.01

Catia, Version 5 Geometry Interface 2024 R2.02

Catia, Version 5 Geometry Interface 2024 R2.03

Catia, Version 6 Geometry Interface 2024 R2

Catia, Version 6 Geometry Interface 2024 R2.01

Catia, Version 6 Geometry Interface 2024 R2.02

Catia, Version 6 Geometry Interface 2024 R2.03

Creo Elements/Direct Modeling Geometry Interface 2024 R2

Creo Elements/Direct Modeling Geometry Interface 2024 R2.01

Creo Elements/Direct Modeling Geometry Interface 2024 R2.02

Creo Elements/Direct Modeling Geometry Interface 2024 R2.03

Creo Parametric Geometry Interface 2024 R2

Creo Parametric Geometry Interface 2024 R2.01

Creo Parametric Geometry Interface 2024 R2.02

Creo Parametric Geometry Interface 2024 R2.03

Inventor Geometry Interface 2024 R2

Inventor Geometry Interface 2024 R2.01

Inventor Geometry Interface 2024 R2.02

Inventor Geometry Interface 2024 R2.03

JTOpen Geometry Interface 2024 R2

JTOpen Geometry Interface 2024 R2.01

JTOpen Geometry Interface 2024 R2.02

JTOpen Geometry Interface 2024 R2.03

NX Geometry Interface 2024 R2

NX Geometry Interface 2024 R2.01

NX Geometry Interface 2024 R2.02

NX Geometry Interface 2024 R2.03

Parasolid Geometry Interface 2024 R2

Parasolid Geometry Interface 2024 R2.01

Parasolid Geometry Interface 2024 R2.02

Parasolid Geometry Interface 2024 R2.03

Solid Edge Geometry Interface 2024 R2

Solid Edge Geometry Interface 2024 R2.01

Solid Edge Geometry Interface 2024 R2.02

Solid Edge Geometry Interface 2024 R2.03

SOLIDWORKS Geometry Interface 2024 R2

SOLIDWORKS Geometry Interface 2024 R2.01

SOLIDWORKS Geometry Interface 2024 R2.02

SOLIDWORKS Geometry Interface 2024 R2.03

***** MAPDL COMMAND LINE ARGUMENTS *****

BATCH MODE REQUESTED (-b) = NOLIST

INPUT FILE COPY MODE (-c) = COPY

DISTRIBUTED MEMORY PARALLEL REQUESTED

4 PARALLEL PROCESSES REQUESTED WITH SINGLE THREAD PER PROCESS

TOTAL OF 4 CORES REQUESTED

INPUT FILE NAME = C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD\dummy.dat

OUTPUT FILE NAME = C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD\solve.out

START-UP FILE MODE = NOREAD

STOP FILE MODE = NOREAD

RELEASE= 2024 R2 BUILD= 24.2 UP20240603 VERSION=WINDOWS x64

CURRENT JOBNAME=file0 17:42:44 JAN 08, 2025 CP= 0.094

PARAMETER _DS_PROGRESS = 999.0000000

/INPUT FILE= ds.dat LINE= 0

*** NOTE *** CP = 0.344 TIME= 17:42:45

The /CONFIG,NOELDB command is not valid in a distributed memory

parallel solution. Command is ignored.

*GET _WALLSTRT FROM ACTI ITEM=TIME WALL VALUE= 17.7125000

TITLE=

wbnew--Modal Campbell

ACT Extensions:

LSDYNA, 2024.2

5f463412-bd3e-484b-87e7-cbc0a665e474, wbex

/COM, ANSYSMotion, 2024.2

20180725-3f81-49eb-9f31-41364844c769, wbex

SET PARAMETER DIMENSIONS ON _WB_PROJECTSCRATCH_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_PROJECTSCRATCH_DIR(1) = C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD\

SET PARAMETER DIMENSIONS ON _WB_SOLVERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_SOLVERFILES_DIR(1) = C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-6\MECH\

SET PARAMETER DIMENSIONS ON _WB_USERFILES_DIR

TYPE=STRI DIMENSIONS= 248 1 1

PARAMETER _WB_USERFILES_DIR(1) = C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\user_files\

--- Data in consistent NMM units. See Solving Units in the help system for more

MPA UNITS SPECIFIED FOR INTERNAL

LENGTH = MILLIMETERS (mm)

MASS = TONNE (Mg)

TIME = SECONDS (sec)

TEMPERATURE = CELSIUS (C)

TOFFSET = 273.0

FORCE = NEWTON (N)

HEAT = MILLIJOULES (mJ)

INPUT UNITS ARE ALSO SET TO MPA

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:45 JAN 08, 2025 CP= 0.359

wbnew--Modal Campbell

***** MAPDL ANALYSIS DEFINITION (PREP7) *****

*********** Nodes for the whole assembly ***********

*********** Nodes for all Remote Points ***********

*********** Elements for Body 1 'Surface Body1' ***********

*********** Elements for Body 2 'Surface Body2' ***********

*********** Elements for Body 3 'Surface Body3' ***********

*********** Elements for Body 4 'Surface Body4' ***********

*********** Send User Defined Coordinate System(s) ***********

*********** Set Reference Temperature ***********

*********** Send Materials ***********

*********** Send Sheet Properties ***********

*********** Send General Axisymmetric Properties "General Axisymmetric" *******

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Node Component ***********

*********** Send Named Selection as Element Component ***********

*********** Send Named Selection as Node Component ***********

*********** Create Remote Point "PointMass_RemotePoint" ***********

*********** Create Remote Point "RemotePoint_Bearing1" ***********

*********** Create Remote Point "RemotePoint_Bearing2" ***********

*********** Create Remote Point "RemotePoint_FreeStanding1" ***********

*********** Create Remote Point "RemotePoint_FreeStanding2" ***********

*********** Create Remote Point "PointMass_RemotePoint2" ***********

*********** Create Bearing Connection "RemotePoint_FreeStanding1 To Multiple" *

Real Constant Set For Above Bearing Connection Is 13

*********** Create Bearing Connection "RemotePoint_FreeStanding2 To Multiple" *

Real Constant Set For Above Bearing Connection Is 14

*********** Construct Remote Mass Using Remote Attachment ***********

*********** Construct Remote Displacement ***********

*********** Construct Remote Displacement ***********

*********** Construct Remote Displacement ***********

*********** Construct Remote Displacement ***********

*** Create a component for all remote displacements ***

*********** Define Rotational Velocity ***********

***** ROUTINE COMPLETED ***** CP = 0.531

--- Number of total nodes = 7698

--- Number of contact elements = 142

--- Number of spring elements = 0

--- Number of bearing elements = 0

--- Number of solid elements = 2428

--- Number of condensed parts = 0

--- Number of total elements = 2577

*GET _WALLBSOL FROM ACTI ITEM=TIME WALL VALUE= 17.7125000

***** MAPDL SOLUTION ROUTINE *****

PERFORM A MODAL ANALYSIS

THIS WILL BE A NEW ANALYSIS

PARAMETER _THICKRATIO = 0.000000000

USE QRDAMP MODE EXTRACTION METHOD

EXTRACT 9 MODES

COMPUTE COMPLEX MODE SHAPES: YES

NORMALIZE THE MODE SHAPES TO THE MASS MATRIX

QRDAMP EIGENSOLVER OPTIONS

REUSE EIGENMODES FROM MODESYM FILE: Yes

SYMMETRIZE CONTACT STIFFNESS MATRIX AT ELEMENT LEVEL

CORIOLIS IN STATIONARY REFERENCE FRAME: GYROSCOPIC DAMPING MATRIX WILL BE CALCULATED

ERASE THE CURRENT DATABASE OUTPUT CONTROL TABLE.

WRITE ALL ITEMS TO THE DATABASE WITH A FREQUENCY OF NONE

FOR ALL APPLICABLE ENTITIES

WRITE NSOL ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR ALL APPLICABLE ENTITIES

PRINTOUT RESUMED BY /GOP

WRITE MISC ITEMS TO THE DATABASE WITH A FREQUENCY OF ALL

FOR THE ENTITIES DEFINED BY COMPONENT _ELMISC

EXPAND ALL EXTRACTED MODES

CALCULATE ELEMENT RESULTS AND NODAL DOF SOLUTION

CALCULATE STRESSES IN ANY DOWNSTREAM MODE SUPERPOSITION EXPANSION PASS

DO NOT COMBINE ELEMENT SAVE DATA FILES (.esav) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ELEMENT MATRIX FILES (.emat) AFTER DISTRIBUTED PARALLEL SOLUTION

DO NOT COMBINE ASSEMBLED MATRIX FILES (.full) AFTER DISTRIBUTED PARALLEL SOLUTION

---------------- Campbell diagram point 1 ----------------

CMOMEGA on component= CM_ROTVELCITY137

OMEGAX, OMEGAY, OMEGAZ= 0.10472E-14 0.0000 0.0000

X1, Y1, Z1= 0.0000 0.0000 0.0000

*GET ANSINTER_ FROM ACTI ITEM=INT VALUE= 0.00000000

*IF ANSINTER_ ( = 0.00000 ) NE

0 ( = 0.00000 ) THEN

*ENDIF

*** NOTE *** CP = 0.594 TIME= 17:42:45

The automatic domain decomposition logic has selected the MESH domain

decomposition method with 4 processes per solution.

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 0.609 TIME= 17:42:45

Element shape checking is currently inactive. Issue SHPP,ON or

SHPP,WARN to reactivate, if desired.

*** NOTE *** CP = 0.656 TIME= 17:42:45

The model data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr8

81BD\file0.err ) for these warning messages.

*** SELECTION OF ELEMENT TECHNOLOGIES FOR APPLICABLE ELEMENTS ***

--- GIVE SUGGESTIONS AND RESET THE KEY OPTIONS ---

ELEMENT TYPE 1 IS SOLID272. KEYOPT(6) IS ALREADY SET AS SUGGESTED AND NO

RESETTING IS NEEDED.

ELEMENT TYPE 2 IS SOLID272. KEYOPT(6) IS ALREADY SET AS SUGGESTED AND NO

RESETTING IS NEEDED.

ELEMENT TYPE 3 IS SOLID272. KEYOPT(6) IS ALREADY SET AS SUGGESTED AND NO

RESETTING IS NEEDED.

ELEMENT TYPE 4 IS SOLID272. KEYOPT(6) IS ALREADY SET AS SUGGESTED AND NO

RESETTING IS NEEDED.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:45 JAN 08, 2025 CP= 0.656

wbnew--Modal Campbell

S O L U T I O N O P T I O N S

PROBLEM DIMENSIONALITY. . . . . . . . . . . . .3-D

DEGREES OF FREEDOM. . . . . . UX UY UZ ROTX ROTY ROTZ

ANALYSIS TYPE . . . . . . . . . . . . . . . . .MODAL

EXTRACTION METHOD. . . . . . . . . . . . . .QRDAMP

QRDAMP BASE EIGENSOLVER. . . . . . . . . . .BLOCK LANCZOS

COMPLEX SOLUTION OUTPUT. . . . . . . . . . .ON

OFFSET TEMPERATURE FROM ABSOLUTE ZERO . . . . . 273.15

NUMBER OF MODES TO EXTRACT. . . . . . . . . . . 9

GLOBALLY ASSEMBLED MATRIX . . . . . . . . . . .UNSYMMETRIC

NUMBER OF MODES TO EXPAND . . . . . . . . . . .ALL

ELEMENT RESULTS CALCULATION . . . . . . . . . .ON

*** WARNING *** CP = 0.656 TIME= 17:42:45

Material number 13 (used by element 2435) should normally have at least

one MP or one TB type command associated with it. Output of energy by

material may not be available.

*** NOTE *** CP = 0.672 TIME= 17:42:45

The step data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr8

81BD\file0.err ) for these warning messages.

*** NOTE *** CP = 0.688 TIME= 17:42:45

Internal nodes from 7699 to 7702 are created.

4 internal nodes are used for handling degrees of freedom on pilot

nodes of rigid target surfaces.

*** NOTE *** CP = 0.703 TIME= 17:42:45

Internal nodes from 7699 to 7702 are created.

4 internal nodes are used for handling degrees of freedom on pilot

nodes of rigid target surfaces.

*** NOTE *** CP = 0.750 TIME= 17:42:45

Rigid-constraint surface identified by real constant set 5 and contact

element type 5 has been set up. The degrees of freedom of the rigid

surface are driven by the pilot node 7689 which connects to other

element 2583. Internal MPC will be built.

This pair will be merged with other pair defined by real constant set

11.

The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ

****************************************

*** NOTE *** CP = 0.750 TIME= 17:42:45

Rigid-constraint surface identified by real constant set 7 and contact

element type 7 has been set up. The degrees of freedom of the rigid

surface are driven by the pilot node 7690 which connects to other

element 2435. Internal MPC will be built.

The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ

****************************************

*** NOTE *** CP = 0.750 TIME= 17:42:45

Rigid-constraint surface identified by real constant set 9 and contact

element type 9 has been set up. The degrees of freedom of the rigid

surface are driven by the pilot node 7691 which connects to other

element 2436. Internal MPC will be built.

The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ

****************************************

*** NOTE *** CP = 0.750 TIME= 17:42:45

Rigid-constraint surface identified by real constant set 11 and

contact element type 11 has been set up. The degrees of freedom of

rigid surface are driven by the pilot node 7694. Internal MPC will be

built.

This pair will be merged with other pair defined by real constant set

5.

The used degrees of freedom set is UX UY UZ ROTX ROTY ROTZ

Please verify constraints (including rotational degrees of freedom)

on the pilot node by yourself.

****************************************

*** NOTE *** CP = 0.766 TIME= 17:42:45

Internal nodes from 7699 to 7702 are created.

4 internal nodes are used for handling degrees of freedom on pilot

nodes of rigid target surfaces.

D I S T R I B U T E D D O M A I N D E C O M P O S E R

...Number of elements: 2577

...Number of nodes: 7702

...Decompose to 4 CPU domains

...Element load balance ratio = 1.002

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 1

THERMAL STRAINS INCLUDED IN THE LOAD VECTOR . . YES

CORIOLIS EFFECT IN STATIONARY REF. FRAME . . . ON

REUSE EIGENMODES FOR QRDAMP SOLVER. . . . . . .YES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

MISC ALL _ELMISC

*********** PRECISE MASS SUMMARY ***********

TOTAL RIGID BODY MASS MATRIX ABOUT ORIGIN

Translational mass | Coupled translational/rotational mass

0.38553E-02 0.0000 0.0000 | 0.0000 -0.10217E-17 0.11484E-12

0.0000 0.38553E-02 0.13172E-20 | 0.19954E-17 -0.13482E-18 0.62268

0.0000 0.26458E-20 0.38553E-02 | -0.11484E-12 -0.62268 0.62267E-18

------------------------------------------ | ------------------------------------------

| Rotational mass (inertia)

| 2.7510 0.52043E-10 0.43541E-15

| 0.52043E-10 149.62 -0.11702E-15

| 0.42266E-15 0.47130E-16 149.62

TOTAL MASS = 0.38553E-02

The mass principal axes coincide with the global Cartesian axes

CENTER OF MASS (X,Y,Z)= 161.51 -0.29787E-10 -0.26502E-15

TOTAL INERTIA ABOUT CENTER OF MASS

2.7510 0.33495E-10 0.11312E-15

0.33495E-10 49.050 -0.11702E-15

0.11312E-15 -0.11702E-15 49.050

The inertia principal axes coincide with the global Cartesian axes

*** MASS SUMMARY BY ELEMENT TYPE ***

TYPE MASS

1 0.274552E-03

2 0.769219E-03

3 0.621633E-03

4 0.788881E-03

15 0.140100E-02

Range of element maximum matrix coefficients in global coordinates

Maximum = 14269624.8 at element 1019.

Minimum = 35030 at element 2436.

*** ELEMENT MATRIX FORMULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 441 SOLID272 0.172 0.000390

2 580 SOLID272 0.234 0.000404

3 810 SOLID272 0.578 0.000714

4 597 SOLID272 0.266 0.000445

5 43 CONTA175 0.000 0.000000

6 1 TARGE170 0.000 0.000000

7 28 CONTA175 0.000 0.000000

8 1 TARGE170 0.000 0.000000

9 28 CONTA175 0.000 0.000000

10 1 TARGE170 0.000 0.000000

11 43 CONTA175 0.000 0.000000

12 1 TARGE170 0.000 0.000000

13 1 COMBI214 0.000 0.000000

14 1 COMBI214 0.000 0.000000

15 1 MASS21 0.000 0.000000

Time at end of element matrix formulation CP = 1.8125.

*** GYROSCOPIC DAMPING MATRIX CALCULATED FOR LISTED ELEMENTS:

TYPE NUMBER ENAME

1 441 SOLID272

2 580 SOLID272

3 810 SOLID272

4 597 SOLID272

15 1 MASS21

BLOCK LANCZOS CALCULATION OF UP TO 9 EIGENVECTORS.

NUMBER OF EQUATIONS = 22781

MAXIMUM WAVEFRONT = 263

MAXIMUM MODES STORED = 9

MINIMUM EIGENVALUE = 0.00000E+00

MAXIMUM EIGENVALUE = 0.10000E+31

Memory allocated on only this MPI rank (rank 0)

-------------------------------------------------------------------

Equation solver memory allocated = 14.976 MB

Equation solver memory required for in-core mode = 14.280 MB

Equation solver memory required for out-of-core mode = 8.691 MB

Total (solver and non-solver) memory allocated = 488.140 MB

Total memory summed across all MPI ranks on this machines

-------------------------------------------------------------------

Equation solver memory allocated = 65.311 MB

Equation solver memory required for in-core mode = 62.275 MB

Equation solver memory required for out-of-core mode = 36.311 MB

Total (solver and non-solver) memory allocated = 1140.397 MB

*** NOTE *** CP = 2.328 TIME= 17:42:46

The Distributed Sparse Matrix Solver used by the Block Lanczos

eigensolver is currently running in the in-core memory mode. This

memory mode uses the most amount of memory in order to avoid using the

hard drive as much as possible, which most often results in the

fastest solution time. This mode is recommended if enough physical

memory is present to accommodate all of the solver data.

Process memory required for in-core LANCZOS Workspace = 24.423317 MB

Process memory required for out-of-core LANCZOS Workspace = 1.053017 MB

Total memory required for in-core LANCZOS Workspace = 92.959808 MB

Total memory required for out-of-core LANCZOS Workspace = 4.099365 MB

Lanczos Memory Mode : INCORE

>> Shift # 1 : | : 9 Eigenvalues Converged

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:46 JAN 08, 2025 CP= 2.641

wbnew--Modal Campbell

*** UNDAMPED FREQUENCIES FROM BLOCK LANCZOS ITERATION ***

MODE FREQUENCY (HERTZ)

1 190.0656343486

2 209.1598339837

3 639.9190075061

4 660.1934103669

5 736.4670026947

6 812.1381924377

7 991.3423824664

8 1784.269371768

9 1784.805960465

Time at end of state-space matrix formulation CP = 2.671875.

***** DAMPED FREQUENCIES FROM REDUCED DAMPED EIGENSOLVER *****

COMPLEX FREQUENCY (HERTZ)

MODE STABILITY FREQUENCY MODAL DAMPING RATIO

1 0.0000000 190.06563 j 0.0000000

2 0.0000000 209.15983 j 0.0000000

3 0.0000000 639.91901 j 0.0000000

4 0.0000000 660.19341 j 0.0000000

5 0.0000000 736.46700 j 0.0000000

6 0.0000000 812.13819 j 0.0000000

7 0.0000000 991.34238 j 0.0000000

8 0.0000000 1784.2694 j 0.0000000

9 0.0000000 1784.8060 j 0.0000000

Time at end of eigenproblem resolution CP = 2.671875.

Time at end of mode shape normalization CP = 2.703125.

*** ELEMENT RESULT CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 441 SOLID272 0.062 0.000142

2 580 SOLID272 0.062 0.000108

3 810 SOLID272 0.188 0.000231

4 597 SOLID272 0.156 0.000262

5 43 CONTA175 0.000 0.000000

7 28 CONTA175 0.000 0.000000

9 28 CONTA175 0.000 0.000000

11 43 CONTA175 0.000 0.000000

13 1 COMBI214 0.000 0.000000

14 1 COMBI214 0.000 0.000000

15 1 MASS21 0.000 0.000000

*** NODAL LOAD CALCULATION TIMES

TYPE NUMBER ENAME TOTAL CP AVE CP

1 441 SOLID272 0.000 0.000000

2 580 SOLID272 0.000 0.000000

3 810 SOLID272 0.000 0.000000

4 597 SOLID272 0.000 0.000000

5 43 CONTA175 0.000 0.000000

7 28 CONTA175 0.000 0.000000

9 28 CONTA175 0.000 0.000000

11 43 CONTA175 0.000 0.000000

13 1 COMBI214 0.000 0.000000

14 1 COMBI214 0.000 0.000000

15 1 MASS21 0.000 0.000000

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:49 JAN 08, 2025 CP= 4.844

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 190.066 0.52613E-02 0.11567E-05 0.315019 0.133790E-11 0.328178E-01 0.347031E-09

2 209.160 0.47810E-02 -0.10652E-05 0.290107 0.113466E-11 0.606502E-01 0.294313E-09

3 639.919 0.15627E-02 0.36718E-05 1.000000 0.134819E-10 0.391351 0.349699E-08

4 660.193 0.15147E-02 0.26669E-05 0.726333 0.711251E-11 0.565816 0.184487E-08

5 736.467 0.13578E-02 0.26633E-05 0.725356 0.709339E-11 0.739811 0.183991E-08

6 812.138 0.12313E-02 -0.30911E-05 0.841853 0.955483E-11 0.974184 0.247837E-08

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.974184 0.00000

8 1784.27 0.56045E-03 -0.77988E-06 0.212400 0.608220E-12 0.989104 0.157763E-09

9 1784.81 0.56028E-03 0.66650E-06 0.181520 0.444221E-12 1.00000 0.115224E-09

-----------------------------------------------------------------------------------------------------------------

sum 0.407676E-10 0.105745E-07

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 190.066 0.52613E-02 0.23951E-01 0.696558 0.573664E-03 0.150935 0.148799

2 209.160 0.47810E-02 -0.23245E-01 0.676008 0.540313E-03 0.293095 0.140149

3 639.919 0.15627E-02 0.23857E-01 0.693810 0.569146E-03 0.442841 0.147627

4 660.193 0.15147E-02 0.27745E-01 0.806894 0.769796E-03 0.645380 0.199673

5 736.467 0.13578E-02 0.12841E-01 0.373454 0.164898E-03 0.688765 0.427720E-01

6 812.138 0.12313E-02 -0.34385E-01 1.000000 0.118234E-02 0.999847 0.306680

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999847 0.00000

8 1784.27 0.56045E-03 -0.43658E-03 0.012697 0.190599E-06 0.999897 0.494383E-04

9 1784.81 0.56028E-03 0.62489E-03 0.018173 0.390493E-06 1.00000 0.101288E-03

-----------------------------------------------------------------------------------------------------------------

sum 0.380074E-02 0.985851

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 190.066 0.52613E-02 0.23951E-01 0.696558 0.573664E-03 0.150935 0.148799

2 209.160 0.47810E-02 0.23245E-01 0.676008 0.540313E-03 0.293095 0.140149

3 639.919 0.15627E-02 0.23857E-01 0.693810 0.569146E-03 0.442841 0.147627

4 660.193 0.15147E-02 0.27745E-01 0.806894 0.769796E-03 0.645380 0.199673

5 736.467 0.13578E-02 -0.12841E-01 0.373454 0.164898E-03 0.688765 0.427720E-01

6 812.138 0.12313E-02 0.34385E-01 1.000000 0.118234E-02 0.999847 0.306680

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999847 0.00000

8 1784.27 0.56045E-03 -0.43658E-03 0.012697 0.190599E-06 0.999897 0.494383E-04

9 1784.81 0.56028E-03 -0.62489E-03 0.018173 0.390493E-06 1.00000 0.101288E-03

-----------------------------------------------------------------------------------------------------------------

sum 0.380074E-02 0.985851

-----------------------------------------------------------------------------------------------------------------

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:49 JAN 08, 2025 CP= 4.844

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 190.066 0.52613E-02 0.0000 0.000000 0.00000 0.00000 0.00000

2 209.160 0.47810E-02 0.0000 0.000000 0.00000 0.00000 0.00000

3 639.919 0.15627E-02 0.0000 0.000000 0.00000 0.00000 0.00000

4 660.193 0.15147E-02 0.0000 0.000000 0.00000 0.00000 0.00000

5 736.467 0.13578E-02 0.0000 0.000000 0.00000 0.00000 0.00000

6 812.138 0.12313E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 1784.27 0.56045E-03 0.0000 0.000000 0.00000 0.00000 0.00000

9 1784.81 0.56028E-03 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 190.066 0.52613E-02 0.0000 0.000000 0.00000 0.00000 0.00000

2 209.160 0.47810E-02 0.0000 0.000000 0.00000 0.00000 0.00000

3 639.919 0.15627E-02 0.0000 0.000000 0.00000 0.00000 0.00000

4 660.193 0.15147E-02 0.0000 0.000000 0.00000 0.00000 0.00000

5 736.467 0.13578E-02 0.0000 0.000000 0.00000 0.00000 0.00000

6 812.138 0.12313E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 1784.27 0.56045E-03 0.0000 0.000000 0.00000 0.00000 0.00000

9 1784.81 0.56028E-03 0.0000 0.000000 0.00000 0.00000 0.00000

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 190.066 0.52613E-02 0.0000 0.000000 0.00000 0.00000 0.00000

2 209.160 0.47810E-02 0.0000 0.000000 0.00000 0.00000 0.00000

3 639.919 0.15627E-02 0.0000 0.000000 0.00000 0.00000 0.00000

4 660.193 0.15147E-02 0.0000 0.000000 0.00000 0.00000 0.00000

5 736.467 0.13578E-02 0.0000 0.000000 0.00000 0.00000 0.00000

6 812.138 0.12313E-02 0.0000 0.000000 0.00000 0.00000 0.00000

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.00000 0.00000

8 1784.27 0.56045E-03 0.0000 0.000000 0.00000 0.00000 0.00000

9 1784.81 0.56028E-03 0.0000 0.000000 0.00000 0.00000 0.00000

*** MAPDL BINARY FILE STATISTICS

BUFFER SIZE USED= 16384

19.812 MB WRITTEN ON ELEMENT MATRIX FILE: file0.emat

7.812 MB WRITTEN ON ELEMENT SAVED DATA FILE: file0.esav

10.250 MB WRITTEN ON ASSEMBLED MATRIX FILE: file0.full

1.188 MB WRITTEN ON MODAL MATRIX FILE: file0.mode

1.562 MB WRITTEN ON RESULTS FILE: file0.rst

*************** Write FE CONNECTORS *********

WRITE OUT CONSTRAINT EQUATIONS TO FILE= file.ce

---------------- Campbell diagram point 2 ----------------

CMOMEGA on component= CM_ROTVELCITY137

OMEGAX, OMEGAY, OMEGAZ= 5236.0 0.0000 0.0000

X1, Y1, Z1= 0.0000 0.0000 0.0000

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 4.969 TIME= 17:42:49

Material number 13 (used by element 2435) should normally have at least

one MP or one TB type command associated with it. Output of energy by

material may not be available.

*** NOTE *** CP = 4.984 TIME= 17:42:49

The step data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr8

81BD\file0.err ) for these warning messages.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:50 JAN 08, 2025 CP= 5.109

wbnew--Modal Campbell

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 2

THERMAL STRAINS INCLUDED IN THE LOAD VECTOR . . YES

CORIOLIS EFFECT IN STATIONARY REF. FRAME . . . ON

REUSE EIGENMODES FOR QRDAMP SOLVER. . . . . . .YES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

MISC ALL _ELMISC

*** GYROSCOPIC DAMPING MATRIX CALCULATED FOR LISTED ELEMENTS:

TYPE NUMBER ENAME

1 441 SOLID272

2 580 SOLID272

3 810 SOLID272

4 597 SOLID272

15 1 MASS21

*** WARNING *** CP = 5.750 TIME= 17:42:50

The file0.modesym file does exist and is being used for the QR damp

eigensolution since the ReuseKey is set to ON on the QRDOPT command.

Time at end of state-space matrix formulation CP = 5.765625.

***** DAMPED FREQUENCIES FROM REDUCED DAMPED EIGENSOLVER *****

COMPLEX FREQUENCY (HERTZ)

MODE STABILITY FREQUENCY MODAL DAMPING RATIO

1 0.0000000 169.34208 j 0.0000000

2 0.0000000 232.82032 j 0.0000000

3 0.0000000 629.72205 j 0.0000000

4 0.0000000 657.09846 j 0.0000000

5 0.0000000 755.96914 j 0.0000000

6 0.0000000 814.38603 j 0.0000000

7 0.0000000 991.34238 j 0.0000000

8 0.0000000 1766.8315 j 0.0000000

9 0.0000000 1802.6778 j 0.0000000

Time at end of eigenproblem resolution CP = 5.765625.

Time at end of mode shape normalization CP = 5.765625.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:53 JAN 08, 2025 CP= 7.953

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 169.342 0.59052E-02 0.88522E-06 0.257041 0.783611E-12 0.208125E-01 0.203256E-09

2 232.820 0.42952E-02 -0.89446E-06 0.259726 0.800065E-12 0.420620E-01 0.207524E-09

3 629.722 0.15880E-02 0.28870E-05 0.838314 0.833503E-11 0.263438 0.216198E-08

4 657.098 0.15218E-02 0.34439E-05 1.000000 0.118603E-10 0.578443 0.307636E-08

5 755.969 0.13228E-02 0.24496E-05 0.711281 0.600034E-11 0.737810 0.155639E-08

6 814.386 0.12279E-02 -0.30558E-05 0.887324 0.933810E-11 0.985827 0.242215E-08

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.985827 0.00000

8 1766.83 0.56598E-03 -0.57294E-06 0.166364 0.328255E-12 0.994546 0.851443E-10

9 1802.68 0.55473E-03 0.45316E-06 0.131585 0.205356E-12 1.00000 0.532662E-10

-----------------------------------------------------------------------------------------------------------------

sum 0.376510E-10 0.976608E-08

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 169.342 0.59052E-02 0.19193E-01 0.564651 0.368384E-03 0.110343 0.955531E-01

2 232.820 0.42952E-02 -0.18741E-01 0.551345 0.351226E-03 0.215546 0.911026E-01

3 629.722 0.15880E-02 0.17052E-01 0.501654 0.290770E-03 0.302640 0.754211E-01

4 657.098 0.15218E-02 0.32294E-01 0.950051 0.104288E-02 0.615016 0.270507

5 755.969 0.13228E-02 0.11385E-01 0.334930 0.129613E-03 0.653839 0.336196E-01

6 814.386 0.12279E-02 -0.33992E-01 1.000000 0.115542E-02 0.999924 0.299698

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999924 0.00000

8 1766.83 0.56598E-03 -0.34726E-03 0.010216 0.120592E-06 0.999960 0.312795E-04

9 1802.68 0.55473E-03 0.36634E-03 0.010777 0.134203E-06 1.00000 0.348101E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.333855E-02 0.865968

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 169.342 0.59052E-02 0.19193E-01 0.564651 0.368384E-03 0.110343 0.955531E-01

2 232.820 0.42952E-02 0.18741E-01 0.551345 0.351226E-03 0.215546 0.911026E-01

3 629.722 0.15880E-02 0.17052E-01 0.501654 0.290770E-03 0.302640 0.754211E-01

4 657.098 0.15218E-02 0.32294E-01 0.950051 0.104288E-02 0.615016 0.270507

5 755.969 0.13228E-02 -0.11385E-01 0.334930 0.129613E-03 0.653839 0.336196E-01

6 814.386 0.12279E-02 0.33992E-01 1.000000 0.115542E-02 0.999924 0.299698

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999924 0.00000

8 1766.83 0.56598E-03 -0.34726E-03 0.010216 0.120592E-06 0.999960 0.312796E-04

9 1802.68 0.55473E-03 -0.36634E-03 0.010777 0.134203E-06 1.00000 0.348101E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.333855E-02 0.865968

-----------------------------------------------------------------------------------------------------------------

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:53 JAN 08, 2025 CP= 7.953

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 169.342 0.59052E-02 0.55846E-06 0.567239 0.311872E-12 0.101355 0.808947E-10

2 232.820 0.42952E-02 -0.82728E-06 0.840295 0.684398E-12 0.323778 0.177522E-09

3 629.722 0.15880E-02 0.98452E-06 1.000000 0.969270E-12 0.638781 0.251413E-09

4 657.098 0.15218E-02 0.63675E-07 0.064676 0.405444E-14 0.640099 0.105166E-11

5 755.969 0.13228E-02 0.69326E-06 0.704162 0.480607E-12 0.796291 0.124662E-09

6 814.386 0.12279E-02 -0.33299E-06 0.338228 0.110883E-12 0.832327 0.287613E-10

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.832327 0.00000

8 1766.83 0.56598E-03 -0.48754E-06 0.495207 0.237694E-12 0.909575 0.616542E-10

9 1802.68 0.55473E-03 0.52748E-06 0.535780 0.278239E-12 1.00000 0.721708E-10

-----------------------------------------------------------------------------------------------------------------

sum 0.307702E-11 0.798130E-09

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 169.342 0.59052E-02 0.12977E-01 0.839653 0.168397E-03 0.360343 0.436796E-01

2 232.820 0.42952E-02 -0.15455E-01 1.000000 0.238856E-03 0.871456 0.619554E-01

3 629.722 0.15880E-02 0.65892E-02 0.426349 0.434177E-04 0.964363 0.112619E-01

4 657.098 0.15218E-02 0.25836E-02 0.167172 0.667522E-05 0.978646 0.173145E-02

5 755.969 0.13228E-02 0.15486E-02 0.100204 0.239830E-05 0.983778 0.622082E-03

6 814.386 0.12279E-02 -0.26909E-02 0.174109 0.724070E-05 0.999272 0.187812E-02

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999272 0.00000

8 1766.83 0.56598E-03 -0.51813E-03 0.033525 0.268455E-06 0.999847 0.696330E-04

9 1802.68 0.55473E-03 0.26758E-03 0.017314 0.715997E-07 1.00000 0.185718E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.467325E-03 0.121217

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 169.342 0.59052E-02 -0.12977E-01 0.839653 0.168397E-03 0.360343 0.436796E-01

2 232.820 0.42952E-02 -0.15455E-01 1.000000 0.238856E-03 0.871456 0.619554E-01

3 629.722 0.15880E-02 -0.65892E-02 0.426349 0.434177E-04 0.964363 0.112619E-01

4 657.098 0.15218E-02 -0.25836E-02 0.167172 0.667522E-05 0.978646 0.173145E-02

5 755.969 0.13228E-02 0.15486E-02 0.100204 0.239830E-05 0.983778 0.622082E-03

6 814.386 0.12279E-02 -0.26909E-02 0.174109 0.724070E-05 0.999272 0.187812E-02

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999272 0.00000

8 1766.83 0.56598E-03 0.51813E-03 0.033525 0.268455E-06 0.999847 0.696330E-04

9 1802.68 0.55473E-03 0.26758E-03 0.017314 0.715997E-07 1.00000 0.185718E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.467325E-03 0.121217

-----------------------------------------------------------------------------------------------------------------

---------------- Campbell diagram point 3 ----------------

CMOMEGA on component= CM_ROTVELCITY137

OMEGAX, OMEGAY, OMEGAZ= 10472. 0.0000 0.0000

X1, Y1, Z1= 0.0000 0.0000 0.0000

***** MAPDL SOLVE COMMAND *****

*** WARNING *** CP = 8.062 TIME= 17:42:53

Material number 13 (used by element 2435) should normally have at least

one MP or one TB type command associated with it. Output of energy by

material may not be available.

*** NOTE *** CP = 8.062 TIME= 17:42:53

The step data was checked and warning messages were found.

Please review output or errors file (

C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr8

81BD\file0.err ) for these warning messages.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:53 JAN 08, 2025 CP= 8.219

wbnew--Modal Campbell

L O A D S T E P O P T I O N S

LOAD STEP NUMBER. . . . . . . . . . . . . . . . 3

THERMAL STRAINS INCLUDED IN THE LOAD VECTOR . . YES

CORIOLIS EFFECT IN STATIONARY REF. FRAME . . . ON

REUSE EIGENMODES FOR QRDAMP SOLVER. . . . . . .YES

PRINT OUTPUT CONTROLS . . . . . . . . . . . . .NO PRINTOUT

DATABASE OUTPUT CONTROLS

ITEM FREQUENCY COMPONENT

ALL NONE

NSOL ALL

MISC ALL _ELMISC

*** GYROSCOPIC DAMPING MATRIX CALCULATED FOR LISTED ELEMENTS:

TYPE NUMBER ENAME

1 441 SOLID272

2 580 SOLID272

3 810 SOLID272

4 597 SOLID272

15 1 MASS21

*** WARNING *** CP = 8.734 TIME= 17:42:53

The file0.modesym file does exist and is being used for the QR damp

eigensolution since the ReuseKey is set to ON on the QRDOPT command.

Time at end of state-space matrix formulation CP = 8.765625.

***** DAMPED FREQUENCIES FROM REDUCED DAMPED EIGENSOLVER *****

COMPLEX FREQUENCY (HERTZ)

MODE STABILITY FREQUENCY MODAL DAMPING RATIO

1 0.0000000 145.22813 j 0.0000000

2 0.0000000 264.96486 j 0.0000000

3 0.0000000 607.21391 j 0.0000000

4 0.0000000 654.00922 j 0.0000000

5 0.0000000 800.21313 j 0.0000000

6 0.0000000 820.99584 j 0.0000000

7 0.0000000 991.34238 j 0.0000000

8 0.0000000 1749.5152 j 0.0000000

9 0.0000000 1821.3096 j 0.0000000

Time at end of eigenproblem resolution CP = 8.765625.

Time at end of mode shape normalization CP = 8.78125.

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:56 JAN 08, 2025 CP= 10.906

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 145.228 0.68857E-02 0.78045E-06 0.202867 0.609097E-12 0.176453E-01 0.157990E-09

2 264.965 0.37741E-02 -0.91351E-06 0.237455 0.834506E-12 0.418205E-01 0.216458E-09

3 607.214 0.16469E-02 0.20480E-05 0.532343 0.419419E-11 0.163324 0.108791E-08

4 654.009 0.15290E-02 0.38471E-05 1.000000 0.148001E-10 0.592077 0.383891E-08

5 800.213 0.12497E-02 0.21603E-05 0.561550 0.466705E-11 0.727279 0.121056E-08

6 820.996 0.12180E-02 -0.29812E-05 0.774933 0.888778E-11 0.984754 0.230535E-08

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.984754 0.00000

8 1749.52 0.57159E-03 -0.58641E-06 0.152431 0.343882E-12 0.994716 0.891975E-10

9 1821.31 0.54906E-03 0.42708E-06 0.111014 0.182398E-12 1.00000 0.473111E-10

-----------------------------------------------------------------------------------------------------------------

sum 0.345190E-10 0.895369E-08

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 145.228 0.68857E-02 0.17778E-01 0.518900 0.316040E-03 0.102082 0.819757E-01

2 264.965 0.37741E-02 -0.18066E-01 0.527311 0.326368E-03 0.207501 0.846546E-01

3 607.214 0.16469E-02 0.10557E-01 0.308137 0.111445E-03 0.243498 0.289072E-01

4 654.009 0.15290E-02 0.34260E-01 1.000000 0.117375E-02 0.622624 0.304451

5 800.213 0.12497E-02 0.89202E-02 0.260367 0.795692E-04 0.648325 0.206390E-01

6 820.996 0.12180E-02 -0.32993E-01 0.963017 0.108853E-02 0.999927 0.282348

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999927 0.00000

8 1749.52 0.57159E-03 -0.38055E-03 0.011108 0.144819E-06 0.999974 0.375637E-04

9 1821.31 0.54906E-03 0.28475E-03 0.008311 0.810798E-07 1.00000 0.210308E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.309593E-02 0.803034

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

1 145.228 0.68857E-02 0.17778E-01 0.518900 0.316040E-03 0.102082 0.819757E-01

2 264.965 0.37741E-02 0.18066E-01 0.527311 0.326368E-03 0.207501 0.846546E-01

3 607.214 0.16469E-02 0.10557E-01 0.308137 0.111445E-03 0.243498 0.289072E-01

4 654.009 0.15290E-02 0.34260E-01 1.000000 0.117375E-02 0.622624 0.304451

5 800.213 0.12497E-02 -0.89202E-02 0.260367 0.795692E-04 0.648325 0.206390E-01

6 820.996 0.12180E-02 0.32993E-01 0.963017 0.108853E-02 0.999927 0.282348

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999927 0.00000

8 1749.52 0.57159E-03 -0.38055E-03 0.011108 0.144819E-06 0.999974 0.375637E-04

9 1821.31 0.54906E-03 -0.28475E-03 0.008311 0.810798E-07 1.00000 0.210308E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.309593E-02 0.803034

-----------------------------------------------------------------------------------------------------------------

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:56 JAN 08, 2025 CP= 10.906

wbnew--Modal Campbell

***** PARTICIPATION FACTOR CALCULATION ***** X DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 145.228 0.68857E-02 0.58602E-06 0.416139 0.343424E-12 0.596446E-01 0.890787E-10

2 264.965 0.37741E-02 -0.10344E-05 0.734539 0.107000E-11 0.245478 0.277541E-09

3 607.214 0.16469E-02 0.14082E-05 1.000000 0.198314E-11 0.589903 0.514395E-09

4 654.009 0.15290E-02 0.58556E-06 0.415809 0.342879E-12 0.649453 0.889375E-10

5 800.213 0.12497E-02 0.10423E-05 0.740170 0.108647E-11 0.838147 0.281812E-09

6 820.996 0.12180E-02 -0.64610E-06 0.458799 0.417444E-12 0.910647 0.108278E-09

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.910647 0.00000

8 1749.52 0.57159E-03 -0.50729E-06 0.360230 0.257344E-12 0.955342 0.667509E-10

9 1821.31 0.54906E-03 0.50709E-06 0.360084 0.257135E-12 1.00000 0.666968E-10

-----------------------------------------------------------------------------------------------------------------

sum 0.575783E-11 0.149349E-08

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Y DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 145.228 0.68857E-02 0.14083E-01 0.791251 0.198335E-03 0.284184 0.514449E-01

2 264.965 0.37741E-02 -0.17799E-01 1.000000 0.316789E-03 0.738095 0.821701E-01

3 607.214 0.16469E-02 0.94586E-02 0.531424 0.894647E-04 0.866284 0.232057E-01

4 654.009 0.15290E-02 0.78038E-02 0.438450 0.608990E-04 0.953543 0.157962E-01

5 800.213 0.12497E-02 0.23996E-02 0.134821 0.575818E-05 0.961794 0.149358E-02

6 820.996 0.12180E-02 -0.51238E-02 0.287880 0.262538E-04 0.999412 0.680982E-02

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999412 0.00000

8 1749.52 0.57159E-03 -0.59868E-03 0.033637 0.358422E-06 0.999925 0.929690E-04

9 1821.31 0.54906E-03 0.22819E-03 0.012821 0.520706E-07 1.00000 0.135063E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.697910E-03 0.181027

-----------------------------------------------------------------------------------------------------------------

***** PARTICIPATION FACTOR CALCULATION ***** Z DIRECTION

CUMULATIVE RATIO EFF.MASS

MODE FREQUENCY PERIOD PARTIC.FACTOR RATIO EFFECTIVE MASS MASS FRACTION TO TOTAL MASS

IMAGINARY COMPONENT

1 145.228 0.68857E-02 -0.14083E-01 0.791251 0.198335E-03 0.284184 0.514449E-01

2 264.965 0.37741E-02 -0.17799E-01 1.000000 0.316789E-03 0.738095 0.821701E-01

3 607.214 0.16469E-02 -0.94586E-02 0.531424 0.894647E-04 0.866284 0.232057E-01

4 654.009 0.15290E-02 -0.78038E-02 0.438450 0.608990E-04 0.953543 0.157962E-01

5 800.213 0.12497E-02 0.23996E-02 0.134821 0.575818E-05 0.961794 0.149358E-02

6 820.996 0.12180E-02 -0.51238E-02 0.287880 0.262538E-04 0.999412 0.680982E-02

7 991.342 0.10087E-02 0.0000 0.000000 0.00000 0.999412 0.00000

8 1749.52 0.57159E-03 0.59868E-03 0.033637 0.358422E-06 0.999925 0.929690E-04

9 1821.31 0.54906E-03 0.22819E-03 0.012821 0.520706E-07 1.00000 0.135063E-04

-----------------------------------------------------------------------------------------------------------------

sum 0.697910E-03 0.181027

-----------------------------------------------------------------------------------------------------------------

*GET _NMODALSOLPROC FROM ACTI ITEM=NUMC VALUE= 4.00000000

FINISH SOLUTION PROCESSING

***** ROUTINE COMPLETED ***** CP = 11.047

PRINTOUT RESUMED BY /GOP

*GET _WALLASOL FROM ACTI ITEM=TIME WALL VALUE= 17.7158333

*** MAPDL - ENGINEERING ANALYSIS SYSTEM RELEASE 2024 R2 24.2 ***

Ansys Mechanical Enterprise

00000000 VERSION=WINDOWS x64 17:42:57 JAN 08, 2025 CP= 11.062

wbnew--Modal Campbell

***** MAPDL RESULTS INTERPRETATION (POST1) *****

*** NOTE *** CP = 11.062 TIME= 17:42:57

The model contains an element type ( COMBI214 ) that operates entirely

in the nodal coordinate system. Viewing nodal displacements or forces

in other than the nodal coordinate system may be invalid. See the

elements manual description for more information.

*** NOTE *** CP = 11.062 TIME= 17:42:57

Reading results into the database (SET command) will update the current

displacement and force boundary conditions in the database with the

values from the results file for that load set. Note that any

subsequent solutions will use these values unless action is taken to

either SAVE the current values or not overwrite them (/EXIT,NOSAVE).

PRINT CAMPBELL DIAGRAM

Sorting : ON

X axis unit : rd/s

Driving component : CM_ROTVELCITY137

Printout all frequencies

*** WARNING *** CP = 11.250 TIME= 17:42:57

Sorting process may not be successful due to the shape of some modes.

If results are not satisfactory, try to change the load steps and/or

the number of modes.

***** FREQUENCIES (Hz) FROM CAMPBELL (sorting on) *****

** The driving component is CM_ROTVELCITY137 **

Spin(rd/s) 0.000 5235.988 10471.976

1 BW 190.066 169.342 145.228

2 FW 209.160 232.820 264.965

3 BW 639.919 629.722 607.214

4 BW 660.193 657.098 654.009

5 FW 736.467 755.969 800.213

6 FW 812.138 814.386 820.996

7 991.342 991.342 991.342

8 BW 1784.269 1766.831 1749.515

9 FW 1784.806 1802.678 1821.310

PRINT CAMPBELL DIAGRAM

Sorting : ON

X axis unit : rd/s

Driving component : CM_ROTVELCITY137

Stability value : ON

Printout all frequencies

*** WARNING *** CP = 11.438 TIME= 17:42:57

Sorting process may not be successful due to the shape of some modes.

If results are not satisfactory, try to change the load steps and/or

the number of modes.

***** STABILITY VALUES (Hz) FROM CAMPBELL (sorting on) *****

** The driving component is CM_ROTVELCITY137 **

Spin(rd/s) 0.000 5235.988 10471.976

1 BW 0.000 0.000 0.000

2 FW 0.000 0.000 0.000

3 BW 0.000 0.000 0.000

4 BW 0.000 0.000 0.000

5 FW 0.000 0.000 0.000

6 FW 0.000 0.000 0.000

7 0.000 0.000 0.000

8 BW 0.000 0.000 0.000

9 FW 0.000 0.000 0.000

PRINTOUT RESUMED BY /GOP

PRINTOUT RESUMED BY /GOP

Set Encoding of XML File to:ISO-8859-1

Set Output of XML File to:

PARM, , , , , , , , , , , ,

, , , , , , ,

DATABASE WRITTEN ON FILE parm.xml

EXIT THE MAPDL POST1 DATABASE PROCESSOR

***** ROUTINE COMPLETED ***** CP = 11.594

PRINTOUT RESUMED BY /GOP

*GET _WALLDONE FROM ACTI ITEM=TIME WALL VALUE= 17.7158333

PARAMETER _PREPTIME = 0.000000000

PARAMETER _SOLVTIME = 12.00000000

PARAMETER _POSTTIME = 0.000000000

PARAMETER _TOTALTIM = 12.00000000

*GET _DLBRATIO FROM ACTI ITEM=SOLU DLBR VALUE= 1.00155521

*GET _COMBTIME FROM ACTI ITEM=SOLU COMB VALUE= 0.149815200

*GET _SSMODE FROM ACTI ITEM=SOLU SSMM VALUE= 2.00000000

*GET _NDOFS FROM ACTI ITEM=SOLU NDOF VALUE= 22781.0000

/FCLEAN COMMAND REMOVING ALL LOCAL FILES

--- Total number of nodes = 7698

--- Total number of elements = 2577

--- Element load balance ratio = 1.00155521

--- Time to combine distributed files = 0.1498152

--- Sparse memory mode = 2

--- Number of DOF = 22781

EXIT MAPDL WITHOUT SAVING DATABASE

NUMBER OF WARNING MESSAGES ENCOUNTERED= 8

NUMBER OF ERROR MESSAGES ENCOUNTERED= 0

+--------------------- M A P D L S T A T I S T I C S ------------------------+

Release: 2024 R2 Build: 24.2 Update: UP20240603 Platform: WINDOWS x64

Date Run: 01/08/2025 Time: 17:42 Process ID: 3796

Operating System: Windows 11 (Build: 22631)

Processor Model: Intel(R) Xeon(R) Platinum 8171M CPU @ 2.60GHz

Compiler: Intel(R) Fortran Compiler Classic Version 2021.9 (Build: 20230302)

Intel(R) C/C++ Compiler Classic Version 2021.9 (Build: 20230302)

Intel(R) oneAPI Math Kernel Library Version 2023.1-Product Build 20230303

Number of machines requested : 1

Total number of cores available : 8

Number of physical cores available : 4

Number of processes requested : 4

Number of threads per process requested : 1

Total number of cores requested : 4 (Distributed Memory Parallel)

MPI Type: INTELMPI

MPI Version: Intel(R) MPI Library 2021.11 for Windows* OS

GPU Acceleration: Not Requested

Job Name: file0

Input File: dummy.dat

Core Machine Name Working Directory

-----------------------------------------------------

0 pyworkbench C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD

1 pyworkbench C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD

2 pyworkbench C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD

3 pyworkbench C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\_ProjectScratch\Scr81BD

Latency time from master to core 1 = 3.104 microseconds

Latency time from master to core 2 = 3.049 microseconds

Latency time from master to core 3 = 3.903 microseconds

Communication speed from master to core 1 = 4724.25 MB/sec

Communication speed from master to core 2 = 5233.38 MB/sec

Communication speed from master to core 3 = 4697.23 MB/sec

Total CPU time for main thread : 9.6 seconds

Total CPU time summed for all threads : 11.7 seconds

Elapsed time spent obtaining a license : 0.5 seconds

Elapsed time spent pre-processing model (/PREP7) : 0.1 seconds

Elapsed time spent solution - preprocessing : 0.2 seconds

Elapsed time spent computing solution : 11.5 seconds

Elapsed time spent solution - postprocessing : 0.1 seconds

Elapsed time spent post-processing model (/POST1) : 0.2 seconds

Eigensolver used : QRdamp

Equation solver computational rate : 16.0 Gflops

Sum of disk space used on all processes : 172.0 MB

Sum of memory used on all processes : 651.0 MB

Sum of memory allocated on all processes : 3246.0 MB

Physical memory available : 32 GB

Total amount of I/O written to disk : 0.4 GB

Total amount of I/O read from disk : 5.7 GB

+------------------ E N D M A P D L S T A T I S T I C S -------------------+

*-----------------------------------------------------------------------------*

| |

| RUN COMPLETED |

| |

|-----------------------------------------------------------------------------|

| |

| Ansys MAPDL 2024 R2 Build 24.2 UP20240603 WINDOWS x64 |

| |

|-----------------------------------------------------------------------------|

| |

| Database Requested(-db) 1024 MB Scratch Memory Requested 1024 MB |

| Max Database Used(Master) 5 MB Max Scratch Used(Master) 163 MB |

| Max Database Used(Workers) 1 MB Max Scratch Used(Workers) 161 MB |

| Sum Database Used(All) 8 MB Sum Scratch Used(All) 643 MB |

| |

|-----------------------------------------------------------------------------|

| |

| CP Time (sec) = 11.734 Time = 17:42:58 |

| Elapsed Time (sec) = 15.000 Date = 01/08/2025 |

| |

*-----------------------------------------------------------------------------*

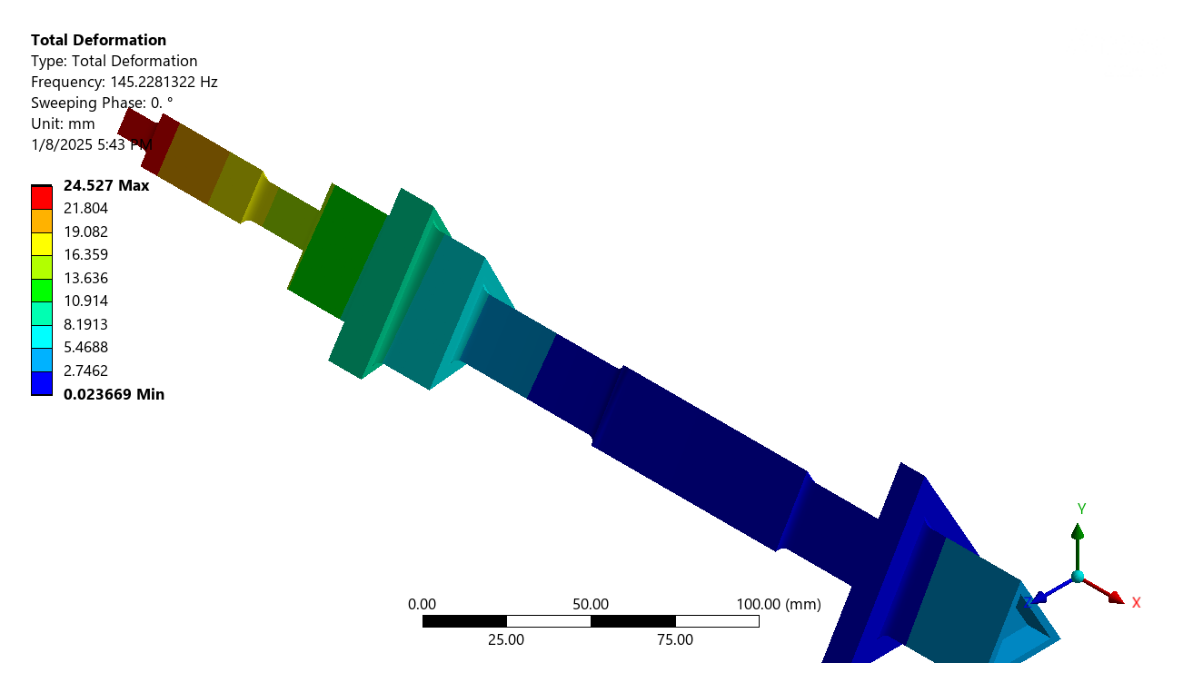

Specify the Mechanical directory path for the Modal Campbell Analysis and fetch the image directory path. Download an image file (tot_deform_2D.png) from the server to the client’s current working directory and display it using matplotlib.

[16]:

from matplotlib import image as mpimg

from matplotlib import pyplot as plt

[17]:

mechanical.run_python_script(f"image_dir=ExtAPI.DataModel.AnalysisList[2].WorkingDir")

result_image_dir_server = mechanical.run_python_script(f"image_dir")

print(f"Images are stored on the server at: {result_image_dir_server}")

Images are stored on the server at: C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-6\MECH\

[18]:

def get_image_path(image_name):

return os.path.join(result_image_dir_server, image_name)

[19]:

def display_image(path):

print(f"Printing {path} using matplotlib")

image1 = mpimg.imread(path)

plt.figure(figsize=(15, 15))

plt.axis("off")

plt.imshow(image1)

plt.show()

[20]:

image_name = "tot_deform_2D.png"

image_path_server = get_image_path(image_name)

[21]:

if image_path_server != "":

current_working_directory = os.getcwd()

local_file_path_list = mechanical.download(

image_path_server, target_dir=current_working_directory

)

image_local_path = local_file_path_list[0]

print(f"Local image path : {image_local_path}")

display_image(image_local_path)

Downloading dns:///127.0.0.1:54649:C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-6\MECH\tot_deform_2D.png to C:\Users\ansys\actions-runner\_work\pyworkbench-examples\pyworkbench-examples\pyworkbench-examples\doc\source\examples\axisymmetric-rotor\tot_deform_2D.png: 100%|██████████| 72.7k/72.7k [00:00<?, ?B/s]

Local image path : C:\Users\ansys\actions-runner\_work\pyworkbench-examples\pyworkbench-examples\pyworkbench-examples\doc\source\examples\axisymmetric-rotor\tot_deform_2D.png

Printing C:\Users\ansys\actions-runner\_work\pyworkbench-examples\pyworkbench-examples\pyworkbench-examples\doc\source\examples\axisymmetric-rotor\tot_deform_2D.png using matplotlib

Specify the Mechanical directory for the Unbalance Response Analysis and fetch the working directory path. Download the solver output file (solve.out) from the server to the client’s current working directory and print its contents.

[22]:

mechanical.run_python_script(f"solve_dir=ExtAPI.DataModel.AnalysisList[3].WorkingDir")

result_solve_dir_server = mechanical.run_python_script(f"solve_dir")

print(f"All solver files are stored on the server at: {result_solve_dir_server}")

All solver files are stored on the server at: C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-7\MECH\

[23]:

solve_out_path = os.path.join(result_solve_dir_server, "solve.out")

[24]:

def write_file_contents_to_console(path):

"""Write file contents to console."""

with open(path, "rt") as file:

for line in file:

print(line, end="")

[25]:

current_working_directory = os.getcwd()

mechanical.download(solve_out_path, target_dir=current_working_directory)

solve_out_local_path = os.path.join(current_working_directory, "solve.out")

write_file_contents_to_console(solve_out_local_path)

os.remove(solve_out_local_path)

Downloading dns:///127.0.0.1:54649:C:\Users\ansys\AppData\Local\Temp\WB_ansys_19944_2\wbnew_files\dp0\SYS-7\MECH\solve.out to C:\Users\ansys\actions-runner\_work\pyworkbench-examples\pyworkbench-examples\pyworkbench-examples\doc\source\examples\axisymmetric-rotor\solve.out: 100%|██████████| 70.7k/70.7k [00:00<?, ?B/s]

Ansys Mechanical Enterprise

*------------------------------------------------------------------*

| |

| W E L C O M E T O T H E A N S Y S (R) P R O G R A M |

| |

*------------------------------------------------------------------*

***************************************************************

* ANSYS MAPDL 2024 R2 LEGAL NOTICES *

***************************************************************

* *

* Copyright 1971-2024 Ansys, Inc. All rights reserved. *

* Unauthorized use, distribution or duplication is *

* prohibited. *

* *

* Ansys is a registered trademark of Ansys, Inc. or its *

* subsidiaries in the United States or other countries. *

* See the Ansys, Inc. online documentation or the Ansys, Inc. *

* documentation CD or online help for the complete Legal *

* Notice. *

* *

***************************************************************

* *

* THIS ANSYS SOFTWARE PRODUCT AND PROGRAM DOCUMENTATION *

* INCLUDE TRADE SECRETS AND CONFIDENTIAL AND PROPRIETARY *

* PRODUCTS OF ANSYS, INC., ITS SUBSIDIARIES, OR LICENSORS. *

* The software products and documentation are furnished by *

* Ansys, Inc. or its subsidiaries under a software license *

* agreement that contains provisions concerning *

* non-disclosure, copying, length and nature of use, *

* compliance with exporting laws, warranties, disclaimers, *

* limitations of liability, and remedies, and other *

* provisions. The software products and documentation may be *

* used, disclosed, transferred, or copied only in accordance *

* with the terms and conditions of that software license *

* agreement. *

* *

* Ansys, Inc. is a UL registered *

* ISO 9001:2015 company. *

* *

***************************************************************

* *

* This product is subject to U.S. laws governing export and *

* re-export. *

* *

* For U.S. Government users, except as specifically granted *

* by the Ansys, Inc. software license agreement, the use, *

* duplication, or disclosure by the United States Government *

* is subject to restrictions stated in the Ansys, Inc. *

* software license agreement and FAR 12.212 (for non-DOD *

* licenses). *

* *

***************************************************************

2024 R2

Point Releases and Patches installed:

Ansys Service Pack 2024 R2.01

Ansys Service Pack 2024 R2.02

Ansys Service Pack 2024 R2.03

Ansys, Inc. License Manager 2024 R2

Ansys, Inc. License Manager 2024 R2.01

Ansys, Inc. License Manager 2024 R2.02

Ansys, Inc. License Manager 2024 R2.03

Discovery 2024 R2

Discovery 2024 R2.01

Discovery 2024 R2.02

Discovery 2024 R2.03

Core WB Files 2024 R2

Core WB Files 2024 R2.01

Core WB Files 2024 R2.02

Core WB Files 2024 R2.03

SpaceClaim 2024 R2

SpaceClaim 2024 R2.01

SpaceClaim 2024 R2.02

SpaceClaim 2024 R2.03

Icepak (includes CFD-Post) 2024 R2

Icepak (includes CFD-Post) 2024 R2.01

Icepak (includes CFD-Post) 2024 R2.02

Icepak (includes CFD-Post) 2024 R2.03

CFD-Post only 2024 R2

CFD-Post only 2024 R2.01

CFD-Post only 2024 R2.02

CFD-Post only 2024 R2.03

CFX (includes CFD-Post) 2024 R2

CFX (includes CFD-Post) 2024 R2.01

CFX (includes CFD-Post) 2024 R2.02

CFX (includes CFD-Post) 2024 R2.03

Chemkin 2024 R2

Chemkin 2024 R2.01

Chemkin 2024 R2.02

Chemkin 2024 R2.03

EnSight 2024 R2

EnSight 2024 R2.01

EnSight 2024 R2.02

EnSight 2024 R2.03

FENSAP-ICE 2024 R2

FENSAP-ICE 2024 R2.01

FENSAP-ICE 2024 R2.02

FENSAP-ICE 2024 R2.03

Fluent (includes CFD-Post) 2024 R2

Fluent (includes CFD-Post) 2024 R2.01

Fluent (includes CFD-Post) 2024 R2.02

Fluent (includes CFD-Post) 2024 R2.03

Polyflow (includes CFD-Post) 2024 R2

Polyflow (includes CFD-Post) 2024 R2.01

Polyflow (includes CFD-Post) 2024 R2.02

Polyflow (includes CFD-Post) 2024 R2.03

Forte (includes EnSight) 2024 R2

Forte (includes EnSight) 2024 R2.01

Forte (includes EnSight) 2024 R2.02

Forte (includes EnSight) 2024 R2.03

ICEM CFD 2024 R2

ICEM CFD 2024 R2.01

ICEM CFD 2024 R2.02

ICEM CFD 2024 R2.03

TurboGrid 2024 R2

TurboGrid 2024 R2.01

TurboGrid 2024 R2.02

TurboGrid 2024 R2.03

Speos 2024 R2

Speos 2024 R2.01

Speos 2024 R2.02

Speos 2024 R2.03

Speos HPC 2024 R2

Speos HPC 2024 R2.01

Speos HPC 2024 R2.02

Speos HPC 2024 R2.03

optiSLang 2024 R2

optiSLang 2024 R2.01

optiSLang 2024 R2.02

optiSLang 2024 R2.03

Remote Solve Manager Standalone Services 2024 R2

Remote Solve Manager Standalone Services 2024 R2.01

Remote Solve Manager Standalone Services 2024 R2.02

Remote Solve Manager Standalone Services 2024 R2.03

Additive 2024 R2

Additive 2024 R2.01

Additive 2024 R2.02

Additive 2024 R2.03

Aqwa 2024 R2

Aqwa 2024 R2.01

Aqwa 2024 R2.02

Aqwa 2024 R2.03

Autodyn 2024 R2

Autodyn 2024 R2.01

Autodyn 2024 R2.02

Autodyn 2024 R2.03

Customization Files for User Programmable Features 2024 R2

Customization Files for User Programmable Features 2024 R2.01

Customization Files for User Programmable Features 2024 R2.02

Customization Files for User Programmable Features 2024 R2.03

LS-DYNA 2024 R2

LS-DYNA 2024 R2.01

LS-DYNA 2024 R2.02

LS-DYNA 2024 R2.03

Mechanical Products 2024 R2

Mechanical Products 2024 R2.01

Mechanical Products 2024 R2.02

Mechanical Products 2024 R2.03

Motion 2024 R2

Motion 2024 R2.01

Motion 2024 R2.02

Motion 2024 R2.03

Sherlock 2024 R2

Sherlock 2024 R2.01

Sherlock 2024 R2.02

Sherlock 2024 R2.03

Sound - SAS 2024 R2

Sound - SAS 2024 R2.01

Sound - SAS 2024 R2.02

Sound - SAS 2024 R2.03

ACIS Geometry Interface 2024 R2

ACIS Geometry Interface 2024 R2.01

ACIS Geometry Interface 2024 R2.02

ACIS Geometry Interface 2024 R2.03

AutoCAD Geometry Interface 2024 R2

AutoCAD Geometry Interface 2024 R2.01

AutoCAD Geometry Interface 2024 R2.02

AutoCAD Geometry Interface 2024 R2.03

Catia, Version 4 Geometry Interface 2024 R2

Catia, Version 4 Geometry Interface 2024 R2.01

Catia, Version 4 Geometry Interface 2024 R2.02

Catia, Version 4 Geometry Interface 2024 R2.03

Catia, Version 5 Geometry Interface 2024 R2

Catia, Version 5 Geometry Interface 2024 R2.01

Catia, Version 5 Geometry Interface 2024 R2.02

Catia, Version 5 Geometry Interface 2024 R2.03

Catia, Version 6 Geometry Interface 2024 R2

Catia, Version 6 Geometry Interface 2024 R2.01

Catia, Version 6 Geometry Interface 2024 R2.02

Catia, Version 6 Geometry Interface 2024 R2.03

Creo Elements/Direct Modeling Geometry Interface 2024 R2

Creo Elements/Direct Modeling Geometry Interface 2024 R2.01

Creo Elements/Direct Modeling Geometry Interface 2024 R2.02

Creo Elements/Direct Modeling Geometry Interface 2024 R2.03

Creo Parametric Geometry Interface 2024 R2

Creo Parametric Geometry Interface 2024 R2.01

Creo Parametric Geometry Interface 2024 R2.02

Creo Parametric Geometry Interface 2024 R2.03

Inventor Geometry Interface 2024 R2

Inventor Geometry Interface 2024 R2.01

Inventor Geometry Interface 2024 R2.02

Inventor Geometry Interface 2024 R2.03

JTOpen Geometry Interface 2024 R2

JTOpen Geometry Interface 2024 R2.01

JTOpen Geometry Interface 2024 R2.02

JTOpen Geometry Interface 2024 R2.03

NX Geometry Interface 2024 R2

NX Geometry Interface 2024 R2.01

NX Geometry Interface 2024 R2.02

NX Geometry Interface 2024 R2.03

Parasolid Geometry Interface 2024 R2

Parasolid Geometry Interface 2024 R2.01

Parasolid Geometry Interface 2024 R2.02

Parasolid Geometry Interface 2024 R2.03

Solid Edge Geometry Interface 2024 R2